Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

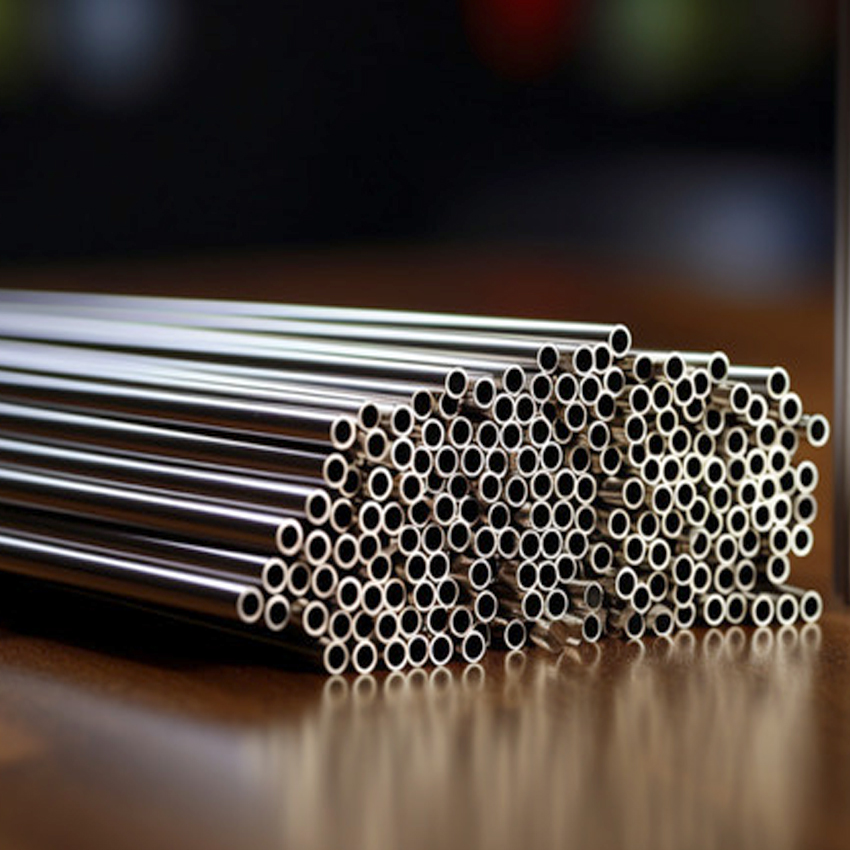

As a key component of the engine duct system, GH2742 capillary tubes directly impact the reliability and safety of the entire engine system. From a practical application perspective, Zhongxing Nickel Alloy offers a detailed explanation of the technical advantages of this material.

The aircraft engine duct system is responsible for transporting vital media such as fuel, lubricating oil, hydraulic oil, air, and oxygen, operating under extremely complex conditions. The ducts must withstand high temperatures and high pressures while also coping with vibration, thermal expansion, and contraction. Failure of any single duct could lead to severe accidents, which imposes very stringent requirements on the material performance.

Temperatures in the engine combustion chamber can reach 800–1100°C, and certain areas may even reach 1400–2700°C, placing extremely high demands on the material’s high-temperature resistance. Additionally, the duct system must endure high-pressure environments and continuous vibration during engine operation. Under such harsh conditions, ordinary materials fail to meet the requirements.

GH2742, a nickel-based superalloy, demonstrates satisfactory comprehensive performance in aircraft engine duct applications. This alloy maintains good mechanical strength and stability even at temperatures above 600°C, which is fundamental to its suitability for aerospace engine use.

From a technical parameter standpoint, GH2742 capillary tubes exhibit excellent high-temperature mechanical properties. The material retains high tensile strength and yield strength at elevated temperatures while also possessing good elongation, ensuring that the ducts do not suffer brittle fracture under complex stress conditions. Its precise dimensional control guarantees compatibility within the complex piping systems of aircraft engines.

In numerous aerospace manufacturing projects, GH2742 capillary tubes show outstanding resistance to thermal fatigue. Frequent temperature cycling in engines poses a significant challenge to materials, but GH2742’s excellent thermal fatigue resistance effectively extends the service life of piping systems.

From a processability perspective, GH2742 offers excellent hot and cold working capabilities, which are critical for manufacturing complex-shaped capillary tubes. In actual production, processes such as cold rolling and cold drawing are employed, followed by appropriate heat treatments to ensure stable material performance. Welding performance is another key factor—GH2742 demonstrates good weldability, ensuring reliable connections between the capillary tubes and other components during engine assembly, thereby reducing leakage risks.

When selecting GH2742 capillary tubes, several factors must be prioritized: stability of chemical composition, which directly determines the material’s high-temperature performance; dimensional accuracy, as precise tolerances are foundational for ensuring the duct system’s sealing integrity; and surface quality, since any minor defects may develop into cracks under extreme conditions.

In practical use, we recommend strict adherence to aircraft engine duct design principles during selection and installation. The piping system should have flexibility and the ability to compensate for thermal expansion autonomously, along with sufficient strength reserves and favorable vibration characteristics. Additionally, all pipe connections must be designed with secure locking measures to ensure the overall reliability of the system.

As a critical material for aircraft engine ducts, GH2742 capillary tubes provide a reliable solution with their high-temperature performance, precise dimensional control, and excellent processability. With the continuous advancement of localization technology, we are confident that this material will play an increasingly important role in the future development of aircraft engines.

If you have any further questions about the application of GH2742 capillary tubes in aircraft engine ducts, please feel free to contact us. Jiangsu Zhongxing Nickel Alloy Materials Co., Ltd. specializes in the R&D and manufacturing of high-temperature alloys, nickel-based alloys, and other advanced precision capillary tubes, offering professional technical support and solutions.

Contact Number: 19145729409 — We are dedicated to serving you.

content is empty!

content is empty!