Nuclear Power Field

In pressurized water reactor (PWR) nuclear power plants, most of the components in both the nuclear island and conventional island are made from steel materials. Exceptions include parts like nuclear fuel cladding, control rod drive mechanisms, and steam generator heat transfer tubes, which are made from zirconium alloys and nickel-based alloys. The rest of the equipment is constructed using steel.

1.Primary Coolant Loop Piping

The primary coolant loop piping plays a vital role in preventing the leakage of nuclear fission products into the containment under normal, abnormal, accident, and test conditions. As a result, it must withstand high temperatures, high pressures, and corrosion. In third-generation AP1000 PWR nuclear power plants, the primary coolant loop piping is made from forged 316LN austenitic stainless steel, known for its excellent strength and corrosion resistance.

2.Reactor Pressure Vessel (RPV)

The RPV operates under extreme conditions, including high temperatures, high pressures, fluid erosion, corrosion, and intense neutron irradiation. With a design lifespan of at least 40 years, the RPV cannot be replaced. Therefore, its material must meet rigorous requirements: high purity, density, and uniformity; strong strength and good toughness; exceptional resistance to irradiation embrittlement and aging; excellent weldability; and superior corrosion resistance. Currently, A508-3 is the preferred material for large PWR pressure vessels.

3.Steam Generator

The steam generator transfers heat from the primary coolant to the secondary loop, converting it into steam to drive the turbine for power generation. The generator’s shell—comprising the upper head, upper shell, lower shell, and transition cone—is made from ferritic steel plates. The U-shaped heat transfer tubes are now commonly fabricated from nickel-based alloys such as 690 and 800. The tube sheet is forged from high-strength low-alloy steel, with a stainless steel cladding layer on the primary coolant side to enhance corrosion resistance.

4.Nuclear-Grade Valves

Nuclear-grade valves are essential components in nuclear power plants, connecting more than 300 subsystems. These valves include gate valves, globe valves, check valves, butterfly valves, safety valves, main steam isolation valves, ball valves, diaphragm valves, pressure-reducing valves, and control valves.

Materials for nuclear-grade valves must offer excellent corrosion resistance, irradiation resistance, impact resistance, and resistance to intergranular corrosion. As a result, low-carbon or ultra-low-carbon austenitic stainless steels are typically used for valve bodies, while high-strength, high-toughness alloys resistant to high temperatures, high pressures, erosion, and wear are chosen for valve stems and sealing surfaces. Stainless steel valves account for approximately 55% of all nuclear-grade valves.

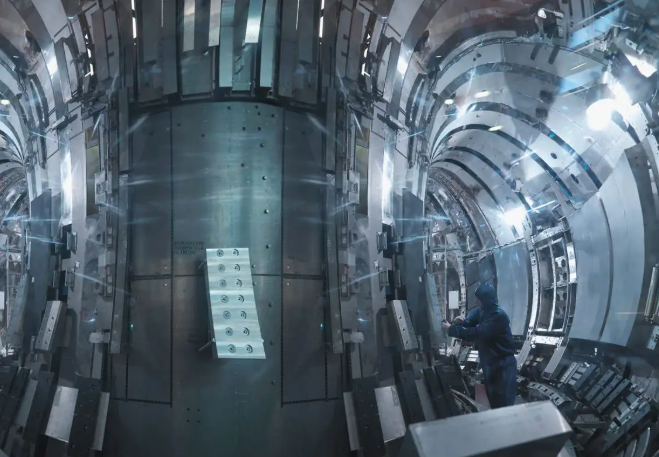

5.Reactor Internals

Reactor internals refer to all structural components inside the reactor pressure vessel, excluding the fuel assemblies and related parts. These components are numerous, structurally complex, and must withstand high temperatures, high pressures, neutron irradiation, and coolant corrosion. The material selection criteria for reactor internals include moderate strength with good toughness, impact and fatigue resistance, low neutron absorption, and minimal induced radioactivity. They must also offer excellent irradiation and corrosion resistance, good compatibility with coolants, low thermal expansion, and superior weldability and machinability.

In second-generation PWRs, the primary materials for reactor internals are austenitic stainless steels, such as 304L, 304LN, 321, 347, and 310, with bolts made from 316LN and 321H stainless steel. Special components, like hold-down springs, use martensitic stainless steel (e.g., 1Cr13).

In third-generation AP1000 PWRs, which have higher power outputs and longer lifespans, stricter requirements are placed on the composition and performance of reactor internals. The main structural material used is forged F304 and F304H austenitic stainless steel, while hold-down springs use an improved 403 martensitic stainless steel.